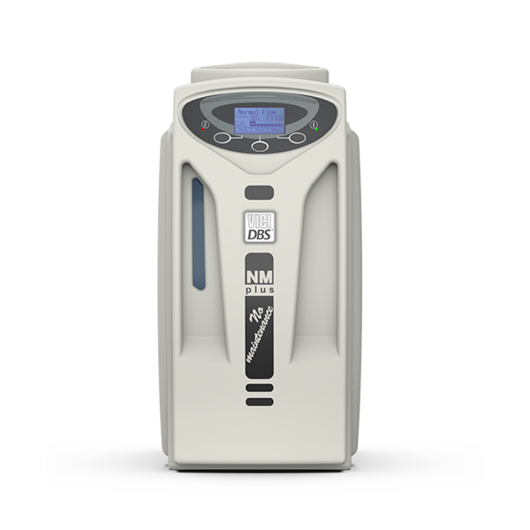

NM PLUS HYDROGEN GENERATOR

The VICI DBS ® hydrogen generators offer the optimum combination of safe operation, reliability and performance. Designed as a hazard free alternative to high-pressure cylinders, all that is required is deionized water and a standard electrical supply for weeks of continuous operation.

Utilizing our proprietary Proton Exchange Membrane (PEM) inside a 100% titanium cell provides superior generator performance and cell life. The exclusive high pressure cold static automatic drying system eliminates the requirement for desiccant cartridges along with the associated downtime and cost. The final purification stage uses a no maintenance cold dual dynamic regeneration system that increases the purity to +99.99996%. Innovative software control allows unrivaled operational performance and safety as well as the additional options of auto water feed, remote networking and cascading for built in redundancy.

With a maximum output capacity of 1350 mL/min, one generator can supply up to 33 GCs. The compact design allows the generator to be installed directly in the laboratory eliminating the requirement for long gas lines and guaranteeing the delivery of high purity gas to your GC.

A sophisticated control system connected to an easy to use touch screen control continuously monitors vital operating parameters to ensure a safe and consistent performance. Built in sensors will shut the generator down if internal/external leaks are present, contaminated water, low water or over pressure. This is why the VICI DBS generators meet the strict safety guidelines to be certified for CE, FCC and MET (CSA and UL compliant)

FEATURES

▪︎ Produces a continuous supply of H2

▪︎ On-demand supply 24/7

▪︎ Flow rate: 100 to 1350 mL/min

▪︎ Purity: +99.99996%

▪︎ Pressure: 11 barg (160 psig)

▪︎ Proprietary 100% titanium cell technology

▪︎ Unique permeation membrane drying system

▪︎ Cold dual dynamic regeneration dryer

▪︎ USB connectivity

▪︎ Easy to install, operate and maintain

Benefits

▪︎ Eliminates dangerous high pressure cylinders helping to keep your employees safer

▪︎ Removes the logistics, inconvenience, downtime and costs of a cylinder system

▪︎ Flow capacity to match your specific instrument demands

▪︎ Ideal for all GC detector applications

▪︎ Meet and exceeds the requirements for the most demanding GC applications

▪︎ Superior hydrogen production with reliable long life cell

▪︎ Minimal maintenance - no desiccant cartridges to change

▪︎ PC monitoring for maintenance, diagnostics and remote connection

▪︎ Peace of mind

▪︎ Improve your laboratory work flow and productivity

Applications

GC APPLICATIONS

▪︎ GC/MS CARRIER GAS

▪︎ GC CARRIER GAS

▪︎ GC FUEL GAS

▪︎ GC-ELCD & HALL

▪︎ ELCD REACTION GAS

SPECTROSCOPY APPLICATIONS

▪︎ ICP-MS COLLISION CELL REACTION GAS

ANALYZER APPLICATIONS

▪︎ TOTAL HYDROCARBON ANALYZER (THA) FUEL GAS

▪︎ CHEMISORPTION/PHYSISORPTION MEASUREMENT GAS

OTHER LAB APPLICATIONS

▪︎ CHEMICAL VAPOR DEPOSITION INSTRUMENTATION (CVD)

▪︎ Plasma Cleaning Instrumentation (UCP)

▪︎ High Efficiency Process Gas

▪︎ Hydrogenation Reactors

▪︎ Hydrogen Fuel Cells

▪︎ Weather Balloon Filling

▪︎ Electronic Nose (eNOSE)

▪︎ 3-D Chromatography

Options

▪︎ I/O board

▪︎ Remote control software (RS232 or USB)

▪︎ Cascading hardware (standard or high purity)

▪︎ Auto-refill

Technical specifications

| Models & Specs | NM PLUS 100 | NM PLUS 160 | NM PLUS 250 | NM PLUS 300 | NM PLUS 400 | NM PLUS 500 | NM PLUS 600 | NM PLUS 1000 | NM PLUS 1350 |

|---|---|---|---|---|---|---|---|---|---|

| Flow mL/min | 100 | 160 | 250 | 300 | 400 | 500 | 600 | 1000 | 1350 |

| Purity | +99.99996% | ||||||||

| Dew point at 7 barg (100 psig) | -73 °C (-103 °F) | ||||||||

| Outlet pressure barg (psig) | -1.4 to 11 (20 to 160) | ||||||||

| Technology | EM (Proton Exchange Membrane) - 100% Titanium cell | ||||||||

| Drying system | No Maintenance Cold Dual Dynamic Regeneration System | ||||||||

| Deionized water quality | Minimum < 1 micro S/cm @25ºC - 1 Mohm-cm@25ºC - ASTM IIRecommended < 0.2 microS/cm @25ºC - 5 Mohm-cm @25ºC - ASTM II | ||||||||

| Internal water tank (liters) | 2.5 | ||||||||

| Safety | Automatic shut down - internal/external hydrogen leak, overpressure and low water | ||||||||

| Display | Touch screen with operating parameters, system status and safety alarms | ||||||||

| LED indicators | Power on/off, system ready, errors | ||||||||

| Interface | USB mod A | ||||||||

| Electrical supply | 110-120V 60Hz / 220-240V 50Hz | ||||||||

| Power consumption (watts) | 100 | 120 | 165 | 205 | 210 | 220 | 255 | 385 | 410 |

| Dimensions mm (inches) | 230W x 480H x 370D (9W x 19H x 15D) | ||||||||

| Weight kg (lbs) | 14 (31) | 14 (31) | 15 (33) | 15 (33) | 15 (33) | 16 (35) | 16 (35) | 17 (37.5) | 18 (38.5) |

| Shipping dimensions mm (in) | 580W x 570H x 400D (22.8W x 22.4H x 15.7D) | ||||||||

| Shipping weight kg (lbs) | 18 (39.5) | 18 (39.5) | 19 (42) | 19 (42) | 19 (42) | 20 (44) | 20 (44) | 21 (46) | 22 (48 |

| Operating temp oC (oF) | 15 to 35 (59 to 95) | ||||||||

| Outlet connection | 1/8" Compression | ||||||||

| Certification | CE, FCC, MET (UL and CSA compliant) | ||||||||

Karlstraße 80/1

72581 Dettingen an der Erms

Germany

Tel.: 07123/9102100

Fax: 07123/889749

Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!